Ready to ship today,

Delivery time appr. 1-3 workdays

Prices incl. VAT plus shipping costs

Depending on the delivery address, the VAT may vary at checkout. Dear store customers of AMB-ELEKTRIK. As of 01.01.2023, the inflation surcharge of +4.9% for materials and energy. must be adjusted to +7.9%.

Your team from AMB-ELEKTRIK

- Order number: 06082807

- EAN-Nr.: 4251610704925

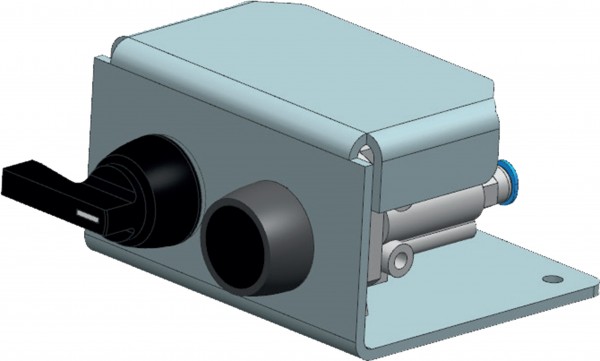

Powerful universal motor with pneumatic tool change system and digital control option - extremely robust and optimized for milling work of any kind - especially suitable for use on gantry milling machines and/or CNC routers. The FME-W DI with 1400 watts offers a completely new concept. The gearbox is located in a robust aluminum body. The motor is attached directly and torsionally rigid to the portal via 4 threaded connections. Changing of cutters etc. is done pneumatically - either automatically via controller control or also manually with a change-over valve. This turns this spindle into a real CNC system. DI stands for direct control via the controller. There, the speed required for the application can be selected or programmed directly. This reduces noise; the duty cycle can be increased; wear is reduced. Motor, bearings, seals are designed for use at longer duty cycles. Solid shaft control electronics ensures equal speed even during hard milling operations. Speed preselection and soft start are a matter of course with AMB. Motor is insulated for maximum safety against external influences. The electronics are perfectly protected against dust and external influences by complete potting - in comparison, other suppliers often work with unprotected electronics with a shorter service life. Electronic thermal overload protection protects against overheating. Original carbon brushes Made in Germany - with integrated cut-off. This prevents the collector from being damaged when the carbon is worn out. Additional silicone cushions between carbon and contact spring ensure long service life due to vibration damping. Versatile application possibilities - for mounting in e.g.: CNC gantries (routers), routers, milling devices, drill stands,... The collet chuck is held by a steep taper SK20 with ER16 transition. This is industry standard and available everywhere in the world. Unmatched light weight with only 3.2 kg. Exceptionally slim design for the smallest possible space requirement during installation and ergonomically pleasant handling during free use, e.g. as a straight grinder or similar. Quick-change power cord can be changed directly on the unit and is available in lengths of up to 7.5 meters. The original Kress power cord module is technically unrivaled and makes it possible to change the power supply directly at the machine. The power supply does not have to be changed at the source (socket). It couldn't be simpler. This also allows several devices to be supplied with only "one" cable during changeover.

| Absorbed power: | 1400 | Watt |

| Speed: | 3.500...22.000 | 1/min |

| Attachment to the portal: | Bohrbild mit 4x M8 | mm |

| Collet: | SK20 + ER 16-8 | mm |

| Weight : | 3,2 | kg |

| Power Supply : | Netzkabelmodul 4 | m |

FAQ

F: What type of pneumatic valves are required? A: 3/2 way.

F: How is the unit attached to the gantry? A: Four fastening threads M6, 10 deep, tightening torque 7Nm, and four dowel pins hole 5H7 10 deep as anti-rotation. No 43mm clamping neck is required.

.F: What system pressure is required? A: The system pressure should be, for 3-4m hose with inner diameter 6mm, 6bar. Basically, the longer the lines from the compressor to the consumer, the larger the pressure accumulator and the line cross-section must be. With 6mm and 3-4m length, 6bar is sufficient.

.F: What air consumption should I expect? A: The main air consumption occurs when flushing/blowing the cone clean. Since this process only lasts for a few seconds, a consumption of approx. 2-3 liters can be assumed during this short period.

F: What is the main air consumption?

F: What is the torsional force on the tool holder? A: The torsional force of the SK20 tool holder on the cutter is 5Nm.

.F: How does the spindle behave at 0V control voltage? A: At 0V, the spindle stands still, from about 1-9V, the speed runs from minimum to maximum value, from 9-10V, the spindle runs at maximum speed.

.F: What is the current consumption at the supply voltage 10...29V DC? A: The power supply unit for the power supply must be able to supply at least 40 mA DC.

.F: What is the input resistance of the control input 0-10V? A: This is about 36 kOhm.

F: How should the ejector position be positioned in the Z direction? A: the closer the ejector position is to the grip position, the less risk there is of tilting the tool holder. We recommend programming the tool change 0.1-0.2mm above the deposit position.

Milling motor with tool change system, SK20 tool holder with ER15 union nut, operating instructions, 4m power cable module.